128oz Water Bottle

The 64/128oz water bottle is made by stainless steel 304 (18/8), double wall vacuum insulated.

OEM service: color, logo and package of bottles can be customized as your requests.

ODM service: making a vital shape of bottle as your drawings.

If you’re interested, please don’t hesitate to contact us and get your personal solution!

Table Of Contents For This Page

Explore the comprehensive Table of Contents for this page, your gateway to in-depth insights and information. From the basics of stainless steel water bottles to their specialized advantages, each section unfolds a unique aspect of this versatile material. Dive into the topics that pique your interest, and navigate effortlessly through the wealth of knowledge we’ve curated for you. Let this Table of Contents be your guide to understanding the world of stainless steel water bottle, their applications, and the numerous benefits they bring to various industries.

Hot Products

These insulated water bottles are hot selling. You can pick and send inquiry to us to check the prices. If you want any other bottles, please send pictures to us, and we will help you find reliable suppliers.

Wide Mouth Water Bottle

- Size: 14/18/22/32/40/64oz

- Material: 304 stainless steel

- Color: Black/White/Navy/Red or customized

- Logo: Laser or screen printing

- Package: White or color box

- Double Wall Vacuum Insulated

Wide Mouth Water Bottle

- Size: 20/26/36oz

- Material: 304 stainless steel

- Color: Black/White/Navy/Red or customized

- Logo: Laser or screen printing

- Package: White or color box

- Double Wall Vacuum Insulated

Sport Water Bottle

- Size: 12/16/20oz

- Material: 304 stainless steel

- Color: Black/White/Navy/Red or customized

- Logo: Laser or screen printing

- Package: White or color box

- Double Wall Vacuum Insulated

Water Jug

- Size: 64/128oz

- Material: 304 stainless steel

- Color: Black/White/Navy/Red or customized

- Logo: Laser or screen printing

- Package: White or color box

- Double Wall Vacuum Insulated

Cola Shaped Bottle

- Size: 350/500/750/1000ml

- Material: 304 stainless steel

- Color: Black/White/Navy/Red or customized

- Logo: Laser or screen printing

- Package: White or color box

- Double Wall Vacuum Insulated

Small Mouth Bottle

- Size: 500/750ml

- Material: 304 stainless steel

- Color: Black/White/Navy/Red or customized

- Logo: Laser or screen printing

- Package: White or color box

- Double Wall Vacuum Insulated

Sport Water Bottle

- Size: 500/750ml

- Material: 304 stainless steel

- Color: Black/White/Navy/Red or customized

- Logo: Laser or screen printing

- Package: White or color box

- Double Wall Vacuum Insulated

Travel Mug

- Size: 500ml

- Material: 304 stainless steel

- Color: Black/White/Navy/Red or customized

- Logo: Laser or screen printing

- Package: White or color box

- Double Wall Vacuum Insulated

Double Wall Water Bottle

- Size: 350/500ml

- Material: 304 stainless steel

- Color: Black/White/Navy/Red or customized

- Logo: Laser or screen printing

- Package: White or color box

- Double Wall Vacuum Insulated

Thermal Water Bottle

- Size: 350/500ml

- Material: 304 stainless steel

- Color: Black/White/Navy/Red or customized

- Logo: Laser or screen printing

- Package: White or color box

- Double Wall Vacuum Insulated

Vacuum Flask

- Size: 1000/1500ml

- Material: 304 stainless steel

- Color: Black/White/Navy/Red or customized

- Logo: Laser or screen printing

- Package: White or color box

- Double Wall Vacuum Insulated

Thermos

- Size: 12/16/20oz

- Material: 304 stainless steel

- Color: Black/White/Navy/Red or customized

- Logo: Laser or screen printing

- Package: White or color box

- Double Wall Vacuum Insulated

Kid Series

- 12/14/16oz bottles are suitable for kids using in school. And there are special stickers.

Promotional Gift Set

- Water bottles, notebooks, pens, etc. can be put into one gift box as your requests.

Sublimation Series

- There are various of bottles and tumblers can be sublimated by your own designs.

Boost Your Sales

- Better Insulation Performance: double wall stainless steel, vacuum insulated. Keep cold to 24 hours+, keep hot to 12 hours+.

- Excellent Leakproof: It won’t leak when you put the bottles or mugs into your bags when you are outside.

- Durable Enough: The bottles and lids won’t break when dropped from 1 meter high.

- Higher Firmness of Surface: The painting and powder-coated surface won’t fade in daily using.

Ready to Ship

- Adequate Inventory: There are various bottles and mugs in stock, which are colored already for your choosing.

- Low MOQ: 100pcs per design can be supported for set-up brand or private business.

- Door to Door Shipping: Your orders can be sent to the address required or Amazon FBA, you don’t need to do anything about custom or shipping.

Purchase Process

transform visions into tailored products. Explore the possibilities and witness firsthand the power of personalized manufacturing.

Step 1: Consultation

At first, you need to confirm the models of bottles needed.

If you have favorate ones or want to make same ones as famous brands. Please send pictures to us to check.

If you don’t have, you can pick models from our hot selling ones.

Meantime, you can discuss the purpose of the new projects with us. Such as new business, expanding your product series, finding a new supplier, etc. And the personal solution will be made for you.

Step 2: Customized Service

There are two types of customized service: OEM and ODM.

OEM: you can pick the bottles in stock, and the color, logo printing, lids, accessories and packages can be customized as your requests.

ODM: creating a total new bottles as your designs. We will make the moulds to produce the bottles with your drawings.

After the customzied requests confirmed, the mockup will be made by us, so you can see your bottles clearly.

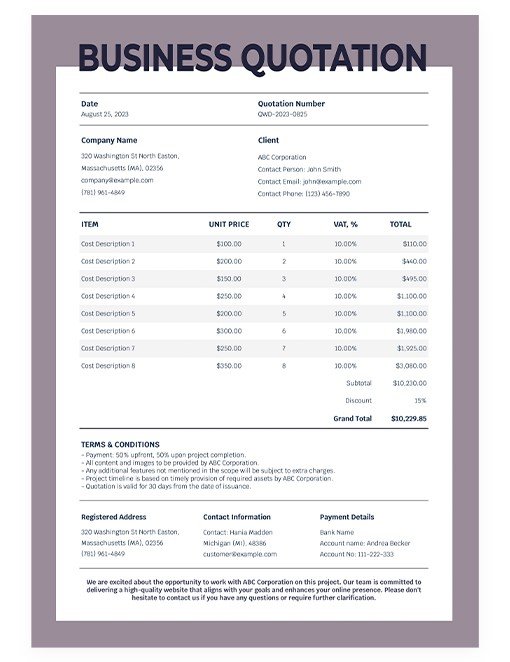

Step 3: Quotation

After models of bottle confirmed, the quick quotation will be provided.

We have worked with more than 50 factories for many years, and many orders are processing.

So our prices can be better than yours.

And we will choose the suitable factory whose price is lower and lead time is shorter for you.

Step 4: Sample Making

After quotation approved, you can make a sample to check if everything of bottles that meet your demand.

You can see the colors and logo printing, and test the performance of leakproof and insulation.

The sample time is around 5-7 days.

Step 5: Final Solution and Order

After sample testing, if there are anything need to be improved, we will make as your requests.

If sample approved, we are going to arrange the production for you.

There are much more bottles and mugs are in stock, click and download our catalog now!

Who are we?

ShinyStar Flask Sourcing has worked with more than 1000 customers to customize their water bottle series.

Are you also facing these issues?

- Don’t know which bottles are hot-selling now;

- Don’t know how to customize a bottle;

- Suffer the unstable product quality and unexpected lead time of old supplier;

- Difficult to find a supplier who can provide spare parts to build up your brand.

… …

Now, we try our best to solve these issues and meet all your demands: customized service, quality assurance, shorter lead time, all spare parts sourcing, strict quality control…

Production Process

Metal Working: 7-10 days

The entire process is as below:

- Stainless steel tube cutting: the tubes are cut one by one for exact size;

- Water expanding or stretching: the cut tubes will be an original bottle shape;

- Shapping: the top and bottom of bottles will be shaped;

- Welding: the inner and outer walls will be welded together to be a bottle;

- Cleaning: washing the inner and outer walls of the bottle;

- Vaccum: extracting the air between the inner and outer walls, now the bottles are insulated;

- Polishing: the outer wall will be polished, and ready for surface treatment;

- Testing: the surface damaged and non-insulated ones will be discarded.

Normally, blank bottles of hot selling ones are in stock, so you don’t need to wait for long time, and the MOQ can be lower.

Surface Treatment: 1-2 days

There are different surface treatments:

Solid or gradient color:

- Painting: the outer wall is painted, the surface is smooth. The advantage is the price is lower, the disadvantage is that is easy to stratch;

- Powder coating: the surface is matte and durable enough for dishwasher. It is the best selling.

Multi-colored patterns:

- air/water/heat transfer: it can be different designs, and the surface is smooth, the disadvantage is that the designs are re-shaped;

- 3D/4D printing: your designs can be 100% made on the bottles, but the price is higher.

Please send the requests of your designs, the suitable solutions will be made for you.

Logo Printing: 1-2 days

There are different methods of logo printing on stainless steel water bottles.

Solid color:

- Laser logo: Laser is used to remove the paint or plastic powder on the bottle surface, so that the silver base color will appear and become the logo design;

- Screen printing: the logo will be made of ink used on a customized design screen.

Multi-color:

- Heat transfer

- 3D/4D printing: it is growing popular now.

Embossed logo: the logo will be embossed on the surface by customzied moulds.

Please send your logo design to us to choose the suitable one.

Packaging: 1-2 days

All packages can be customzied as your requests.

- Egg crate;

- White/Color box;

- Cylinder box;

- Wrapper/ hang tag;

- Thank you card.

Strict Quality Control

These tests will be made during the production and before the shipping.

- Leakproof test;

- Insulated test;

- Dishwasher test;

- Cross-cut test

To ensure the quality of each bottle in every process.

Flexible Shipping Plan

If you have a forwarder, you just need to send the contact to us, the remaining things of shipping will be handled by us.

Or, if you don’t have a forwarder, we can help you ship the bottles. Door to door (DDP), FBA service, etc. are all supported.

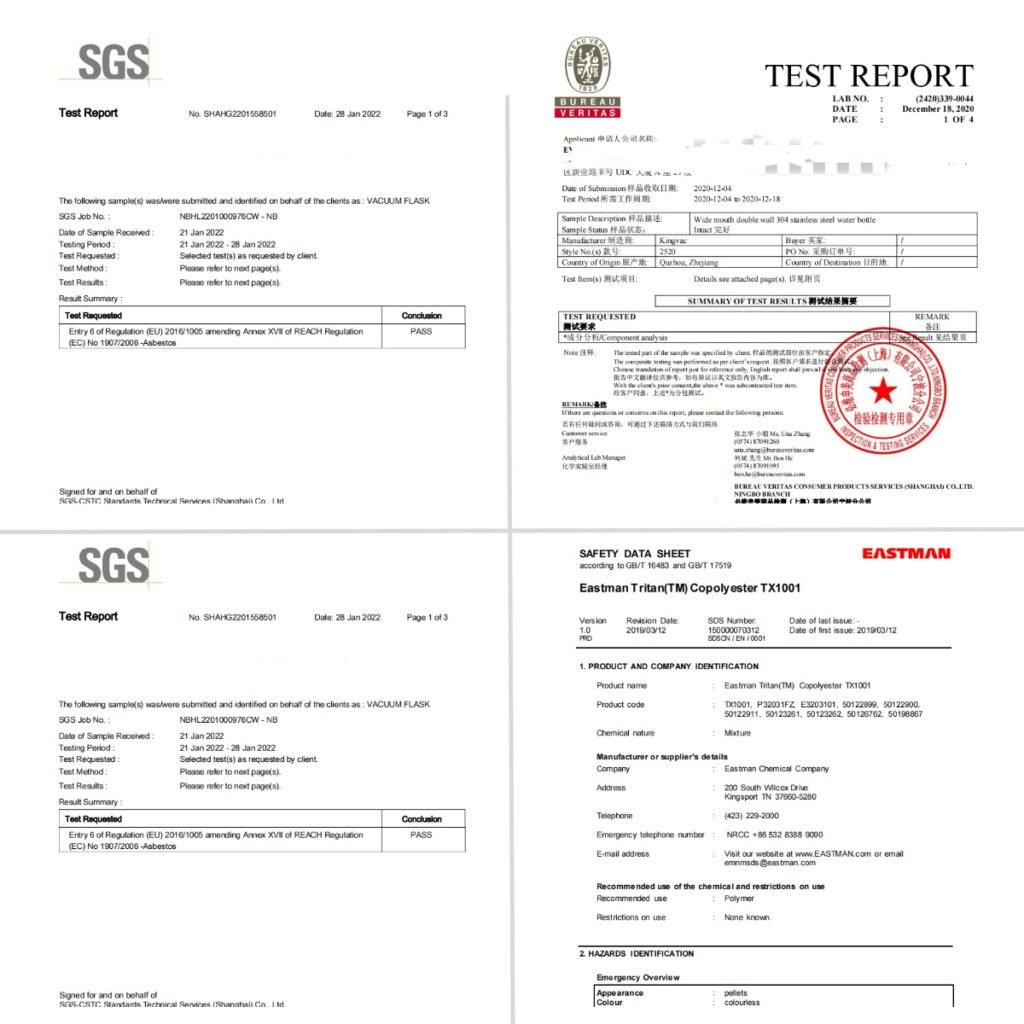

Product's Certification

If certifications of water bottles are required, we can help you make the tests in China, and send the reports with your company title to you. Such as, FDA, LFGB, etc.

1,000+ Satisfied Clients Over The Globe

"Your team did an amazing job recommending hot-selling stainless steel water bottles that our customers absolutely love. It's been a pleasure working with you."

Purchasing Manager, Green Earth Co.

"We are thrilled with the customized stainless steel water bottles. The design and quality are top-notch, and the customization process was seamless."

Director of Operations, Fitness First

"Thank you for assisting us in procuring various accessories along with the water bottles. The shipment was complete and arrived on time."

Owner, Pure Hydration

"Your team’s support in transporting our goods has been invaluable. The logistics were handled perfectly, ensuring a smooth delivery."

General Manager, Urban Adventures

"The bulk order process was efficient and hassle-free. The water bottles are durable and of excellent quality."

Sales Director, Outdoor Essentials

"The personalized water bottles have been a hit with our clients. The customization options provided were fantastic!"

Founder, Healthy Hydration

"Your team’s recommendation on the latest designs really paid off. The water bottles are stylish and functional, and our sales have increased."

Head of Marketing, Pure Wellness

"The quality of the stainless steel water bottles exceeded our expectations. The fast shipping and efficient customer service were much appreciated."

Contact us to get free Samples and Catalogs.

Able

able@insulflaskio.com

Let's start your business

This section aims to address common questions and provide insightful answers to help you better understand the characteristics, applications, and care of Stainless Steel Water Bottles.

Q1: Where to Find the Manufacturer of 128oz Water Bottle?

A: Finding a manufacturer of stainless steel water bottles, particularly one that can provide high-quality products and meet your specific requirements, involves several steps. Here’s a guide to help you find a reliable manufacturer:

1. Online Directories

– Alibaba: A leading global marketplace where you can find numerous stainless steel water bottle manufacturers, primarily from China. You can compare suppliers, read reviews, and request samples.

– Made-in-China: Another popular platform where you can browse a variety of manufacturers specializing in stainless steel products.

– Global Sources: A B2B marketplace where you can find verified suppliers of stainless steel water bottles.

– ThomasNet: This platform connects North American buyers with manufacturers, and it includes stainless steel water bottle manufacturers.

2. Trade Shows

– Canton Fair (China Import and Export Fair): One of the largest trade fairs in China where you can meet a wide range of suppliers, including stainless steel water bottle manufacturers.

– Global Sources Trade Shows: Held in Hong Kong, this show is an excellent opportunity to meet suppliers face-to-face.

– International Home + Housewares Show: Held in Chicago, this show features many manufacturers from around the world, including those specializing in stainless steel water bottles.

3. Industry Associations

– International Association of Stainless Steel Manufacturers (IASM): They often have directories or can recommend manufacturers.

– American Metal Market (AMM): They provide listings and directories of metal manufacturers, including those who might produce stainless steel water bottles.

4. Search Engines

– Use Google or Bing to search for stainless steel water bottle manufacturers. Phrases like “OEM stainless steel water bottle manufacturer” or “custom stainless steel water bottle factory” can yield good results.

– You can also search for specific certifications (like ISO 9001) to find manufacturers that meet quality standards.

5. Local Business Networks

– Chambers of Commerce: They often have listings or can recommend manufacturers.

– Business Networking Events: Attending events in the metal or manufacturing industry can help you make valuable connections.

6. Referrals and Recommendations

– Ask other businesses in your industry for recommendations. Networking with other professionals can often lead to finding a reliable manufacturer.

7. LinkedIn

– LinkedIn can be a useful tool to connect with manufacturers directly. Searching for companies and professionals in the stainless steel water bottle manufacturing industry might lead you to the right supplier.

By exploring these resources, you can find a manufacturer that suits your needs, whether you’re looking for custom designs, specific quantities, or particular quality standards.

Q2: Things to Consider When Purchasing 128oz Water Bottle

A: When purchasing stainless steel water bottles, especially for resale or bulk orders, there are several key factors to consider to ensure you get the best quality and value for your investment. Here’s a comprehensive guide:

1. Material Quality

- Type of Stainless Steel: The most commonly used grades are 18/8 or 304 stainless steel, which are known for their durability, resistance to corrosion, and food-safe properties.

- Certification: Ensure the material meets industry standards such as FDA approval, LFGB certification, or equivalent food-grade certifications.

2. Insulation Technology

- Single vs. Double Wall: Single-wall bottles are lighter and more cost-effective, but they don’t offer insulation. Double-wall bottles provide better insulation, keeping drinks hot or cold for extended periods.

- Vacuum Insulation: This technology enhances thermal retention, making it essential for high-performance bottles.

3. Capacity and Size

- Variety: Consider offering a range of sizes (e.g., 12 oz, 20 oz, 32 oz) to cater to different customer preferences.

- Portability: Size and weight affect portability, which is crucial for customers who want bottles for travel, sports, or everyday use.

4. Design and Customization

- Aesthetics: The design should be visually appealing and align with your brand or target market’s preferences.

- Customization Options: Look for manufacturers that offer customization in terms of colors, logos, patterns, and finishes (e.g., matte, glossy).

- Ergonomics: The bottle should be easy to hold, carry, and drink from, with features like contoured shapes, handle attachments, or carabiners.

5. Lid Types

- Variety: Options like screw-on, flip-top, straw lids, and sports caps can cater to different user needs.

- Leak-Proof Design: A secure, leak-proof lid is essential for preventing spills, especially when the bottle is carried in bags.

- Material: Ensure the lid is made from BPA-free plastic or stainless steel to maintain the bottle’s overall quality and safety.

6. Durability

- Scratch and Dent Resistance: High-quality stainless steel should resist dents and scratches, ensuring the bottle remains in good condition over time.

- Warranty: A manufacturer’s warranty can be an indicator of the product’s durability and the manufacturer’s confidence in their product.

7. Safety and Health Compliance

- BPA-Free: Ensure that the bottle and its components (especially the lid and any inner coatings) are free from harmful chemicals like BPA.

- Testing and Certification: Look for products that have passed safety tests and have the necessary certifications, such as FDA or LFGB, to ensure they are safe for drinking.

8. Price and Minimum Order Quantity (MOQ)

- Cost per Unit: Balance quality with cost, especially when purchasing in bulk. Higher-quality bottles will have a higher cost, but they may offer better resale value.

- MOQ: Be aware of the manufacturer’s minimum order requirements, which can affect your purchasing decision depending on your budget and inventory needs.

9. Lead Time and Shipping

- Production Time: Check the manufacturer’s lead time for production, especially for customized orders.

- Shipping Costs and Time: Factor in shipping costs and time, particularly if the bottles are being manufactured overseas. Consider potential delays due to customs or other factors.

10. Manufacturer’s Reputation

- Reviews and Testimonials: Look for feedback from other customers to gauge the manufacturer’s reliability and the quality of their products.

- Customer Service: A manufacturer with good customer service can make the purchasing process smoother, especially if issues arise with your order.

11. Environmental Impact

- Sustainability: Consider the manufacturer’s environmental practices, such as using recycled materials or sustainable production methods.

- Eco-Friendly Packaging: Opt for manufacturers that use eco-friendly packaging, which can appeal to environmentally-conscious consumers.

12. After-Sales Support

- Warranty and Returns: Ensure there are clear policies for returns, replacements, or warranties in case of defects or issues with the product.

- Spare Parts Availability: Check if spare parts (like lids or gaskets) are available for replacement, which can extend the product’s lifespan.

Q3: How Much does it Cost to Source 128oz Water Bottle?

A: The cost of sourcing stainless steel water bottles can vary widely depending on several factors, including the quality of the materials, the complexity of the design, the quantity ordered, and any customization required. Here’s a breakdown of the potential costs:

1. Base Cost per Unit

- Basic Single-Wall Bottles: Typically range from $1 to $3 per unit. These are usually the most cost-effective option but offer no insulation.

- Double-Wall Vacuum Insulated Bottles: Generally priced between $4 to $10 per unit. These bottles provide insulation to keep beverages hot or cold for longer periods.

- High-End or Specialty Bottles: Can range from $10 to $20 or more per unit, depending on additional features like premium materials, advanced insulation technology, unique designs, or built-in infusers.

2. Customization Costs

- Logo Printing: Adding a logo or custom design typically costs an additional $0.50 to $2 per unit, depending on the complexity and number of colors used.

- Custom Colors or Finishes: Customizing the bottle’s color or finish (e.g., matte, glossy, powder-coated) might add $0.30 to $1 per unit.

- Engraving or Embossing: More advanced customization like laser engraving or embossing usually costs $1 to $3 per unit.

- Packaging Customization: Custom packaging, such as branded boxes or sleeves, can add $0.50 to $2 per unit.

3. Minimum Order Quantity (MOQ)

- Small Orders: For smaller quantities (e.g., 100-500 units), the cost per unit will be higher, typically within the upper range mentioned above, due to the lower volume.

- Bulk Orders: Larger orders (e.g., 1,000 units or more) generally reduce the cost per unit by 10-30%, depending on the supplier’s pricing structure.

4. Additional Costs

- Molds and Tooling: If you’re ordering a custom design that requires new molds, there may be an upfront cost ranging from $500 to $5,000, depending on the complexity of the design.

- Shipping Costs: Shipping costs vary based on the destination, weight, and volume of the order. For international shipping, costs can range from $0.50 to $5 per unit.

- Import Duties and Taxes: If sourcing from overseas, factor in potential customs duties, taxes, and other import fees, which can add another 5-15% to the total cost.

5. Other Factors Influencing Cost

- Supplier Location: Manufacturers in different regions may offer different pricing. For example, Chinese manufacturers often have lower prices due to scale, but European or North American manufacturers may charge more for local production.

- Lead Time: Expedited production or shipping can increase costs.

- Quality and Certifications: Higher quality materials or certifications (like BPA-free, FDA approval) might add to the cost but ensure a safer, more durable product.

Estimated Costs Example:

- Basic Single-Wall Bottle (No customization, small order): $2 per unit × 500 units = $1,000.

- Double-Wall Vacuum Insulated Bottle (with logo printing, medium order): $7 per unit × 1,000 units = $7,000.

- High-End Custom Bottle (with full customization and custom packaging, large order): $12 per unit × 5,000 units = $60,000.

Q4: How to Choose the 128oz Water Bottle for Your Business?

A: Choosing the right stainless steel water bottles for your business is crucial for ensuring customer satisfaction, brand reputation, and profitability. Whether you’re selling directly to consumers or offering custom bottles as promotional items, here’s a guide to help you make an informed decision:

1. Understand Your Target Market

- Customer Demographics: Identify the preferences of your target audience. Are they outdoor enthusiasts, fitness buffs, corporate clients, or environmentally conscious consumers? This will influence the type of bottle, design, and features you choose.

- Price Sensitivity: Determine how much your customers are willing to pay. This will help you select bottles that balance quality and cost.

- Usage Patterns: Consider how your customers will use the bottles. For instance, athletes might prefer bottles with easy-to-drink spouts, while office workers might prefer sleek, professional designs.

2. Choose the Right Material

- 304 Stainless Steel (18/8): This is the most common grade for stainless steel water bottles due to its corrosion resistance, durability, and food safety.

- 316 Stainless Steel (Marine Grade): If your customers need bottles that withstand harsh environments (e.g., saltwater exposure), this higher-grade steel might be necessary, though it comes at a higher cost.

- Inner Coating: Ensure that any inner coating used is BPA-free and doesn’t affect the taste of the beverages.

3. Decide on Insulation Type

- Single-Wall Bottles: Ideal for cost-sensitive markets or for use in environments where insulation isn’t necessary. These bottles are lightweight and less expensive.

- Double-Wall Vacuum Insulated Bottles: Perfect for customers who need to keep beverages hot or cold for extended periods. These bottles are more versatile and cater to a broader range of needs but are more expensive.

4. Evaluate the Design and Features

- Size and Capacity: Offer a range of sizes to meet different needs (e.g., 12 oz, 20 oz, 32 oz). Larger bottles might appeal to athletes or outdoor enthusiasts, while smaller bottles could be better for daily use.

- Lid Types: Consider offering a variety of lids (e.g., screw-on, flip-top, straw, sports cap) to cater to different preferences. Ensure that lids are leak-proof and easy to clean.

- Portability Features: Features like handles, carabiners, or silicone grips enhance portability, making the bottle more convenient for users on the go.

- Ergonomics: Ensure the bottle is easy to hold and drink from. A well-designed bottle should be comfortable to carry and use.

5. Customization Options

- Branding Opportunities: Choose bottles that can easily be customized with your logo, color schemes, or unique designs. Consider laser engraving for a premium look or screen printing for more vibrant colors.

- Packaging: Custom packaging can enhance the unboxing experience and reinforce your brand identity. Consider eco-friendly packaging options if sustainability is important to your brand.

6. Consider Quality and Durability

- Material Thickness: Thicker stainless steel walls generally indicate higher durability and resistance to dents and scratches.

- Sealing and Leak-Proofing: Test the bottles to ensure they are leak-proof, especially if they are intended for use in bags or backpacks.

- Warranty: A warranty from the manufacturer can indicate confidence in the product’s quality.

7. Factor in Sustainability

- Recyclability: Stainless steel is recyclable, but also consider whether the entire bottle (including the lid) is eco-friendly.

- Manufacturer Practices: If sustainability is a key value for your business, look for manufacturers with eco-friendly practices, such as using recycled materials or reducing carbon footprints in production.

8. Assess Pricing and Profit Margins

- Cost per Unit: Determine the cost of the bottles based on your desired features and customization. Balance this against your target retail price or budget for promotional giveaways.

- MOQ (Minimum Order Quantity): Be mindful of the minimum order requirements, which can impact your initial investment and inventory management.

- Bulk Discounts: Consider the potential savings from ordering in larger quantities, which can improve your profit margins.

9. Check Manufacturer Reliability

- Reputation: Research the manufacturer’s reputation through reviews, testimonials, and industry certifications.

- Lead Time: Ensure the manufacturer can meet your timeline, especially if you’re planning a product launch or promotional campaign.

- After-Sales Support: Reliable customer service and clear return policies are important for addressing any issues that might arise after purchase.

10. Test the Product

- Samples: Always request samples before placing a large order. This allows you to evaluate the product’s quality, functionality, and overall appeal.

- Feedback: Get feedback from a small group of potential customers or team members to ensure the bottle meets their needs and expectations.

Q5: How to Customize the 128oz Water Bottle for Your Brand?

A:

1. Define Your Brand Identity

- Brand Colors: Identify the primary and secondary colors of your brand that should be reflected on the water bottle.

- Logo and Design Elements: Ensure your logo is clear and scalable. Decide if you want other design elements, such as patterns or slogans, to be part of the customization.

- Brand Messaging: Think about what message or values your brand represents and how you can communicate this through the bottle’s design.

2. Choose the Right Bottle Style

- Bottle Type: Select from single-wall, double-wall insulated, sports, or other specialized bottles that align with your brand and customer preferences.

- Size and Shape: Choose the size (e.g., 12 oz, 20 oz, 32 oz) and shape (e.g., cylindrical, tapered) that best fits your market.

- Material Finish: Decide on the finish—matte, glossy, powder-coated, brushed stainless steel, etc. This choice should complement your brand’s aesthetic.

3. Decide on Customization Techniques

- Screen Printing: Ideal for adding vibrant colors and detailed designs. It works well for logos and graphics with multiple colors.

- Laser Engraving: Offers a sleek, premium look. It’s durable and works well for minimalist designs or for adding a touch of elegance.

- Embossing/Debossing: Adds texture to the bottle by raising or recessing the design into the material. This creates a tactile and unique appearance.

- Hydrographic Printing: For intricate patterns or full-wrap designs, hydrographic (or water transfer) printing allows for high-definition customization.

- Pad Printing: Useful for small areas or multi-color designs, particularly on lids or smaller bottle parts.

4. Incorporate Functional Features

- Lid Customization: Customize the lid with your brand colors, or opt for different lid styles (e.g., sports cap, straw lid) that suit your audience.

- Silicone Bands or Grips: Add silicone bands in your brand’s colors, which can be used as grips or decorative elements.

- Carry Straps or Handles: Customize with branded straps, handles, or carabiners that enhance portability.

- Insulation Enhancements: If your brand focuses on high-performance or outdoor activities, consider adding features like copper lining for better insulation.

5. Design for Durability

- Long-Lasting Print: Ensure that the customization method you choose is durable and won’t easily fade, peel, or scratch off, especially for products meant for heavy use.

- Test for Quality: Always test the final design on a sample to ensure it meets your standards in terms of aesthetics and durability.

6. Consider Packaging Customization

- Branded Boxes: Design packaging that reflects your brand identity, using your logo, colors, and other design elements.

- Eco-Friendly Options: If sustainability is part of your brand ethos, consider using recyclable or biodegradable packaging materials.

- Promotional Inserts: Include inserts or flyers that tell the story of your brand, offer care instructions, or provide promotional offers.

7. Evaluate the Cost

- Customization Costs: Different customization techniques come with varying costs. For example, laser engraving might be more expensive than screen printing, but it offers a premium look.

- Bulk Discounts: Many manufacturers offer discounts for larger orders, so consider how much customization you can afford while maintaining profit margins.

- Sample Fees: Request a sample to evaluate the design before placing a bulk order, but keep in mind that there may be a fee for this service.

8. Work with the Manufacturer

- Clear Communication: Provide your manufacturer with detailed instructions, including design files (usually in vector formats like .AI or .EPS), color codes (Pantone), and specifications for placement.

- Approval Process: Ensure you review and approve a prototype or mock-up before full-scale production begins.

- Lead Time: Discuss the timeline for production and delivery, especially if you have a specific launch date or event in mind.

9. Promote Your Customized Bottles

- Marketing Campaigns: Use your customized bottles in marketing campaigns, showcasing their unique design and how they align with your brand values.

- Social Media: Leverage social media platforms to showcase the customization process or the final product, engaging your audience with behind-the-scenes content.

- Events and Giveaways: Use your branded bottles as promotional giveaways or at events to increase brand visibility.

10. Gather Feedback and Iterate

- Customer Feedback: After launching your customized bottles, gather feedback from customers regarding design, functionality, and overall satisfaction.

- Iterate: Use this feedback to improve future designs or to add new features that better align with customer preferences.

Q6: Causes and Solutions for Leaking 128oz Water Bottle

A: Leaking stainless steel water bottles can be a frustrating issue for both manufacturers and consumers. Understanding the causes and implementing solutions can help prevent leaks, improve customer satisfaction, and reduce product returns. Here’s an overview of the common causes of leaks and their corresponding solutions:

Common Causes of Leaks

Poorly Sealed Lids

- Cause: The most common cause of leaks is an improperly sealed lid. This can result from a misaligned lid, a loose fit, or a manufacturing defect in the threading of the bottle or lid.

- Solution: Ensure that the bottle lid is designed with precision threading that aligns perfectly with the bottle’s mouth. Conduct quality checks to ensure that lids fit snugly and securely. Offering lids with silicone or rubber gaskets can create a tighter seal and prevent leaks.

Damaged or Worn-Out Gaskets

- Cause: The gasket, usually made of silicone or rubber, forms a seal between the lid and the bottle. Over time, these gaskets can wear out, crack, or become misaligned, leading to leaks.

- Solution: Use high-quality, durable gasket materials that are resistant to wear and tear. Consider offering replacement gaskets for customers. Encourage users to check the gasket regularly and replace it if signs of wear are evident.

Cross-Threading

- Cause: Cross-threading occurs when the lid is screwed on incorrectly, causing the threads to not align properly. This can damage the threads and prevent a proper seal.

- Solution: Educate customers on how to correctly screw on the lid by first turning it counterclockwise until the threads click into place, then tightening it clockwise. Consider designing bottles with improved thread alignment to minimize the chances of cross-threading.

Manufacturing Defects

- Cause: Defects during the manufacturing process, such as uneven threading, gaps in the lid, or deformities in the bottle’s mouth, can result in leaks.

- Solution: Implement stringent quality control measures during production. Inspect bottles and lids for defects before shipping. Consider offering a warranty or return policy for defective products.

Overfilled Bottles

- Cause: Overfilling the bottle can cause liquid to seep out when the lid is screwed on, especially if the lid displaces liquid as it is closed.

- Solution: Include a fill line on the inside of the bottle or provide clear instructions to customers on the maximum fill level. Design the bottle with a slight lip or ridge inside to prevent overfilling.

Improper Cleaning

- Cause: Residue or dirt on the threads, lid, or gasket can prevent a proper seal, leading to leaks.

- Solution: Advise customers to clean their bottles and lids regularly, paying particular attention to the threads and gasket area. Suggest using a bottle brush and mild detergent for thorough cleaning.

Thermal Expansion

- Cause: Exposure to extreme temperatures can cause the metal to expand or contract, potentially affecting the fit between the lid and the bottle.

- Solution: Design bottles to account for thermal expansion, using materials that can tolerate temperature fluctuations without compromising the seal. Advise customers to avoid over-tightening the lid when the bottle contains hot or cold liquids.

Pressure Build-Up

- Cause: If the bottle is used for carbonated drinks or is subjected to high altitudes, pressure can build up inside the bottle, causing leaks or even causing the lid to pop off.

- Solution: Recommend that customers avoid using the bottle for carbonated beverages or provide vented lids designed to release excess pressure safely. Include warnings or instructions about pressure-related risks.

Preventative Measures and Customer Education

Clear Instructions: Provide clear instructions on proper use, including how to correctly seal the lid, the importance of regular cleaning, and precautions to take with hot or carbonated liquids.

Product Testing: Before launching a new product, conduct extensive testing under different conditions (e.g., various temperatures, liquid types, and user handling scenarios) to identify and mitigate potential leak risks.

Customer Support: Offer responsive customer support to address any leakage issues. Providing easy access to replacement parts, such as lids or gaskets, can help maintain customer satisfaction.

Design Innovations: Continuously improve product designs by incorporating feedback from customers and keeping up with advances in materials and manufacturing techniques that enhance the bottle’s seal and durability.

Q7: Certifications of 128oz Water Bottle

A: Certifications for stainless steel water bottles help ensure that they meet safety, quality, and environmental standards. These certifications are crucial for compliance, consumer trust, and market acceptance. Here are some key certifications to consider:

1. FDA (Food and Drug Administration)

- Description: In the U.S., the FDA regulates food contact materials, including stainless steel water bottles. Certification ensures that the material is safe for contact with food and beverages.

- Importance: Validates that the bottle is made from food-grade materials and does not leach harmful substances.

2. LFGB (Lebensmittel- und Futtermittelgesetzbuch)

- Description: This is a German regulation that governs food contact materials in Europe. LFGB certification ensures that the product meets stringent safety standards for food contact.

- Importance: Provides assurance of safety and quality for products sold in European markets.

3. ISO 9001

- Description: ISO 9001 is an international standard for quality management systems. It ensures that the manufacturer follows consistent quality control procedures.

- Importance: Indicates that the manufacturer adheres to international quality management practices, which can lead to better product consistency and reliability.

4. ISO 14001

- Description: This certification focuses on environmental management systems. It ensures that the manufacturer is committed to reducing its environmental impact.

- Importance: Demonstrates the manufacturer’s commitment to sustainable practices and can appeal to environmentally conscious consumers.

5. BPA-Free Certification

- Description: This certification ensures that the product does not contain bisphenol A (BPA), a harmful chemical often found in plastics.

- Importance: Ensures that the bottle is safe for use and does not pose health risks associated with BPA.

6. CE Marking

- Description: The CE mark indicates that the product complies with European health, safety, and environmental protection standards.

- Importance: Required for products sold in the European Economic Area (EEA), it signifies that the product meets EU safety and quality standards.

7. California Prop 65 Compliance

- Description: California Proposition 65 requires businesses to provide warnings about significant exposure to chemicals that cause cancer, birth defects, or reproductive harm.

- Importance: Ensures that products sold in California do not contain harmful levels of toxic chemicals, which is important for compliance in this market.

8. Sustainability Certifications

- Description: Certifications such as the Cradle to Cradle certification or Global Recycled Standard (GRS) focus on sustainability and the use of recycled materials.

- Importance: Demonstrates that the product or manufacturing process is environmentally friendly and contributes to sustainable practices.

9. SGS Certification

- Description: SGS is a global inspection, verification, testing, and certification company. SGS certification can cover various standards, including quality, safety, and environmental impact.

- Importance: Provides an additional layer of assurance regarding the product’s quality and safety.

10. TÜV Rheinland Certification

- Description: TÜV Rheinland offers testing and certification for product safety, quality, and performance.

- Importance: Provides credibility and assurance that the product meets rigorous safety and quality standards.

11. RoHS (Restriction of Hazardous Substances)

- Description: RoHS certification ensures that the product does not contain certain hazardous substances, such as lead, mercury, and cadmium, beyond permissible limits.

- Importance: Ensures that the product is environmentally safe and meets regulations for electronics and other components.

Choosing the Right Certifications

- Market Requirements: Identify the certifications required for your target markets. For example, LFGB and CE may be important for European markets, while FDA and Prop 65 are crucial for the U.S.

- Consumer Expectations: Consider certifications that align with consumer expectations, such as BPA-free or sustainability certifications, to enhance product appeal.

- Manufacturer’s Capabilities: Ensure that the manufacturer is capable of obtaining and maintaining the necessary certifications.

Q8: Inspections of 128oz Water Bottle

A: Inspections of stainless steel water bottles are essential to ensure that they meet quality, safety, and performance standards before they reach consumers. Here’s a detailed guide on the types of inspections you might perform, the aspects to check, and best practices for ensuring product quality:

Types of Inspections

Incoming Material Inspection

- Purpose: Verify the quality and compliance of raw materials used in the manufacturing of stainless steel water bottles.

- What to Check: Material certifications, grade of stainless steel (e.g., 304, 316), and conformity to safety standards. Perform tests for material thickness, composition, and durability.

Pre-Production Inspection

- Purpose: Ensure that manufacturing processes, equipment, and initial samples meet quality standards before full-scale production begins.

- What to Check: Sample bottles for design accuracy, quality of initial production runs, and alignment with specifications. Inspect prototypes for design flaws and functional issues.

In-Process Inspection

- Purpose: Monitor the production process to identify and address issues during manufacturing.

- What to Check: Consistency in product dimensions, proper assembly, alignment of threads, and correct application of customization (e.g., logos, prints). Check for defects like dents, scratches, or poor finish.

Final Quality Inspection

- Purpose: Perform a comprehensive inspection of finished bottles before they are packaged and shipped.

- What to Check: Overall appearance, seal and lid fit, leak-proof testing, and functionality. Inspect for cosmetic defects (e.g., scratches, discoloration) and verify that all customizations are correctly applied.

Leakage Testing

- Purpose: Ensure that bottles do not leak under normal usage conditions.

- What to Check: Perform tests by filling the bottle with liquid and applying pressure (e.g., shaking, inverting). Check for leaks around the lid, seam, and base.

Pressure Testing

- Purpose: Verify the bottle’s ability to withstand internal pressure, especially if used for carbonated beverages or under varying environmental conditions.

- What to Check: Test bottles under different pressure levels to ensure they do not burst or deform.

Temperature Testing

- Purpose: Confirm that insulated bottles maintain their thermal properties and perform as expected under temperature extremes.

- What to Check: Test the bottle’s ability to keep beverages hot or cold for the specified duration. Check for performance in both high and low temperatures.

Certification Compliance Inspection

- Purpose: Ensure that the product meets the required safety and quality certifications.

- What to Check: Verify compliance with certifications like FDA, LFGB, and BPA-free standards. Check for documentation and certification labels.

Q9: Manufacturing Process of 128oz Water Bottle

A: The manufacturing process of stainless steel water bottles involves several key stages, each crucial to ensuring the final product’s quality, durability, and functionality. Here’s a step-by-step overview of the typical manufacturing process:

1. Material Selection

- Stainless Steel Grade: Choose high-quality stainless steel, typically 304 (18/8) or 316 (marine grade) stainless steel, known for its corrosion resistance and durability.

- Material Preparation: The stainless steel sheets or coils are sourced and prepared for forming. They may be treated or cleaned to remove impurities.

2. Cutting and Forming

- Sheet Cutting: Stainless steel sheets are cut into precise sizes and shapes according to the design specifications of the water bottles.

- Deep Drawing: The cut sheets are then subjected to deep drawing, a process where the metal is stretched into a cylindrical shape using a die and punch. This forms the basic body of the bottle.

3. Shaping and Trimming

- Body Formation: The deep-drawn cylinders are further processed to form the desired shape and size. This may involve additional forming steps to refine the bottle’s profile.

- Trimming: Excess material is trimmed away to ensure the top edge of the bottle is smooth and even, ready for the neck and lid to be attached.

4. Welding and Seam Processing

- Welding: The side seams of the bottle are welded to create a sealed, continuous body. This can be done using TIG (Tungsten Inert Gas) welding for precise and strong welds.

- Seam Processing: The welded seam is cleaned and polished to remove any irregularities and ensure a smooth surface.

5. Necking and Finishing

- Necking: The top of the bottle is formed with a neck to accommodate the screw-on lid or cap. This involves rolling the metal into a threaded or smooth neck, depending on the lid design.

- Finishing: The bottle undergoes finishing processes such as sanding, polishing, or brushing to achieve the desired surface texture and appearance. This may include a matte, glossy, or brushed finish.

6. Insulation (for Vacuum-Insulated Bottles)

- Inner Liner: For vacuum-insulated bottles, an inner liner is placed inside the outer shell. This is typically a second layer of stainless steel or a different material.

- Vacuum Sealing: The space between the inner and outer layers is evacuated of air to create a vacuum, which helps maintain the temperature of the contents. This step is critical for ensuring thermal insulation.

7. Lid and Cap Production

- Lid Manufacturing: Lids are made separately and can include features such as screw threads, flip-tops, or straws. The lids are often made from stainless steel, plastic, or a combination.

- Assembly: The lids are assembled with any additional components, such as seals or gaskets, to ensure they fit properly and provide a leak-proof seal.

8. Customization and Branding

- Printing and Engraving: Bottles may undergo custom printing, laser engraving, or embossing to include brand logos, designs, or other markings.

- Final Touches: Any additional custom features, such as silicone grips or handles, are added at this stage.

9. Quality Control

- Inspection: Each bottle undergoes rigorous quality control checks, including visual inspections, leak tests, and pressure tests to ensure they meet safety and quality standards.

- Testing: Products may be tested for durability, insulation performance (for insulated bottles), and compliance with certifications like FDA or LFGB.

10. Packaging and Distribution

- Packaging: Bottles are carefully packaged to prevent damage during transportation. Packaging may include branded boxes, protective materials, and user instructions.

- Distribution: Packaged bottles are then shipped to retailers, distributors, or directly to customers.

11. Post-Production Services

- Customer Support: Offer support for any issues related to the product, such as defects or warranty claims.

- Feedback Loop: Gather feedback from customers to improve future designs and manufacturing processes.

Embark on a journey into the fundamentals of 128oz Water Bottle! In this section, we’ll unravel the basics, shedding light on what makes these coated fabrics unique and versatile. Whether you’re new to the concept or seeking a quick refresher, join us in exploring the essential knowledge surrounding 128oz Water Bottle and discover the myriad applications that make them indispensable in today’s industries.

South America Market Guide: What Distributors Should Know Before Ordering Bulk Water Bottles

South America represents a diverse and opportunity-rich region for bulk water bottle sourcing. With large populations, expanding urban centers, and growing awareness of reusable drinkware, demand continues to rise across multiple countries. At the same time, the region is characterized by uneven purchasing power, complex import environments, and distributor-led sales structures, making strategic product planning essential.

This guide is written for B2B distributors and importers sourcing bulk water bottles for South America, including private-label programs and OEM projects. From a manufacturer’s and exporter’s perspective, it explains how to navigate regional market differences, manage pricing sensitivity, and select water bottle products that can scale across South American distribution networks.

Qatar Market Guide for Travel Mugs: Retail Trends & Import Requirements

Qatar is a compact but high-value market for travel mugs and premium drinkware. With strong purchasing power, a growing hospitality sector, and a consumer base accustomed to international brands, Qatar presents unique opportunities for suppliers who understand its premium orientation, controlled retail environment, and project-driven demand.

Unlike larger Middle Eastern markets, Qatar does not rely on high-volume mass distribution. Instead, demand is shaped by selective retail, corporate gifting, hospitality programs, and travel-related consumption, making product positioning and execution especially important.

UAE Stainless Steel Drinkware Market Insights: Popular Colors, Packaging & Compliance

The United Arab Emirates is one of the most design-driven and brand-conscious drinkware markets in the Middle East. Supported by strong consumer purchasing power, a mature retail environment, and a rapidly growing e-commerce ecosystem, the UAE has become a strategic entry point for international stainless steel drinkware brands targeting the wider Gulf region.

For exporters and OEM manufacturers, the UAE market differs significantly from neighboring countries. While regulatory compliance remains essential, visual presentation, packaging quality, and brand perception play a much more decisive role in buyer decisions.

Saudi Arabia Market Guide: SASO-Approved Stainless Steel Bottles & Buyer Checklist

Saudi Arabia is the largest and most regulation-driven market in the Middle East for stainless steel bottles. With extreme climate conditions, strong purchasing power, and an increasingly structured retail environment, Saudi Arabia represents both a high-potential and high-barrier market for international drinkware suppliers.

For exporters, Saudi Arabia is often the first Middle Eastern market where regulatory readiness directly determines commercial success. Products that fail to meet local compliance requirements can be delayed or rejected regardless of quality or price competitiveness.

Vacuum Insulated Bottles for the Middle East Market SASO Requirements & Hot-Selling Models

The Middle East has become one of the fastest-growing regions for vacuum insulated bottles, driven by extreme climate conditions, rising disposable income, and expanding modern retail infrastructure. In many Middle Eastern countries, insulated drinkware is not a lifestyle accessory but a daily necessity for temperature control, outdoor activity, and long-distance travel.

For international manufacturers and exporters, the Middle East offers strong opportunities—but also distinct challenges. Buyers in this region place exceptional importance on heat resistance, product durability, regulatory compliance, and visual appeal, making it essential to understand both technical and market-specific expectations before entering.

Thailand Market Guide What Retailers and Wholesalers Want in Outdoor Water Bottles

As one of Southeast Asia’s most tourism-driven and outdoor-oriented economies, Thailand represents a unique market for outdoor water bottles. High temperatures, year-round travel activity, and strong participation in outdoor lifestyles have made reusable water bottles a practical necessity rather than a niche product.

For international manufacturers and exporters, Thailand offers solid mid-volume potential supported by both modern retail and traditional wholesale channels. At the same time, buyer expectations are shaped by real-world usage conditions, meaning products must perform reliably in heat, humidity, and frequent transport.

This guide is written for B2B buyers supplying outdoor water bottles to the Thai market, including retailers, wholesalers, distributors, and private-label programs. From a manufacturer’s and OEM exporter’s perspective, it explains how to understand Thai market demand, select suitable outdoor bottle designs, and align product strategies with retailer and wholesaler expectations.

Indonesia Insulated Bottle Market: Import Tips, Pricing & Regulations

As the largest consumer market in Southeast Asia, Indonesia offers enormous volume potential for insulated water bottles. With a population exceeding 270 million and a rapidly expanding urban middle class, demand for affordable and functional drinkware continues to grow. However, Indonesia is also one of the most complex markets in the region when it comes to pricing sensitivity, import procedures, and channel fragmentation.

This guide is written for B2B buyers supplying insulated bottles to the Indonesian market, including importers, distributors, private-label brands, and OEM sourcing teams. From a manufacturer’s and exporter’s perspective, it explains how to navigate import regulations, manage pricing expectations, and select insulated bottle products that can succeed at scale in Indonesia.

Metal Water Bottles for Malaysia Distributors: Market Trends & Product Selection Guide

The Malaysian market for metal water bottles is driven primarily by distribution efficiency, price competitiveness, and broad consumer reach. Unlike highly premium-focused markets, Malaysia relies heavily on distributors and wholesalers to move volume across diverse retail formats, including supermarkets, convenience stores, independent retailers, and promotional channels.

This guide is written for B2B distributors and importers supplying metal water bottles to the Malaysian market. From a manufacturer’s and OEM exporter’s perspective, it explains how to understand local market trends, select the right product mix, and build sustainable distribution-oriented bottle programs in Malaysia.

Drinkware Products for Singapore Retailers: Design Preferences & Quality Standards

As one of Southeast Asia’s most developed and quality-driven markets, Singapore presents unique opportunities—and equally unique challenges—for drinkware suppliers. While the market size is relatively compact, Singapore’s retail environment is highly competitive, brand-conscious, and regulation-aware. Products that succeed here often set the benchmark for broader regional expansion.

This guide is written for B2B buyers supplying drinkware products to Singapore retailers, including brand owners, importers, distributors, and private-label programs. From a manufacturer’s and OEM exporter’s perspective, it explains how to align product design, quality standards, and supply consistency with the expectations of Singapore’s modern retail landscape.

Southeast Asia Market Guide: Best-Selling Insulated Bottles for Singapore, Malaysia & Thailand

Southeast Asia has emerged as one of the fastest-growing regions for insulated water bottles, driven by rising urbanization, expanding middle-class consumption, and increasing awareness of reusable drinkware. For international manufacturers and exporters, the region offers strong volume potential—but it also presents fragmented market structures, diverse buyer expectations, and country-specific purchasing logic.

This guide is written for B2B buyers supplying insulated bottles to Southeast Asia, with a regional focus on Singapore, Malaysia, and Thailand. From a manufacturer’s and OEM exporter’s perspective, it explains how to understand regional demand patterns, identify best-selling insulated bottle types, and build sourcing strategies that work across multiple Southeast Asian markets.

John Smith

CEO, Eco Living Inc.